Uncategorized

How Does a Heat Exchanger Work for Cooling?

The heat exchanger is a linchpin in the world of cooling systems, particularly in chillers. For manufacturers providing chillers to diverse businesses, understanding the role of heat exchangers can be paramount.

This guide will dive into the nuances, design variations, efficiency techniques, and industrial applications associated with heat exchangers in chillers. If you’re a manufacturer looking to better understand chillers for your clients, this resource is for you.

Principles of Heat Transfer in Chiller Systems

In any chiller system, the foundational science rests on the pillars of heat transfer: conduction, convection, and radiation. While radiation plays a minimal role in the typical heat exchanger setup, conduction and convection predominantly drive the process.

Conduction is the direct transfer of heat through a solid material, with molecules passing energy to their neighboring molecules.

Convection, on the other hand, involves the movement of heat between a solid surface and a liquid or gas in motion. In the context of a chiller system, convection is essential as the fluid (typically a refrigerant) circulates through a heat exchanger. It absorbs heat from one source (e.g., a building’s interior) and transfers it to another medium (e.g., the outside air or a cooling tower) through convection. This process helps cool the initial fluid and maintain the desired temperature in the building.

Chiller Heat Exchanger Fundamentals

A heat exchanger, in the context of a chiller unit, is a device meticulously designed to facilitate the efficient transfer of heat from one medium to another without mixing them. This ensures that the target medium is cooled or heated as desired, depending on the specific application.

Different chiller applications warrant different heat exchanger designs. Shell and Tube Exchangers, for instance, comprise a series of tubes. One set of fluid circulates inside these tubes while another circulates outside of them but within the confines of a sealed shell. This design is prized for its reliability and versatility.

Plate Heat Exchangers employ a series of thin, flat plates that create alternate channels for the two fluids and offer a compact design with high heat transfer efficiency.

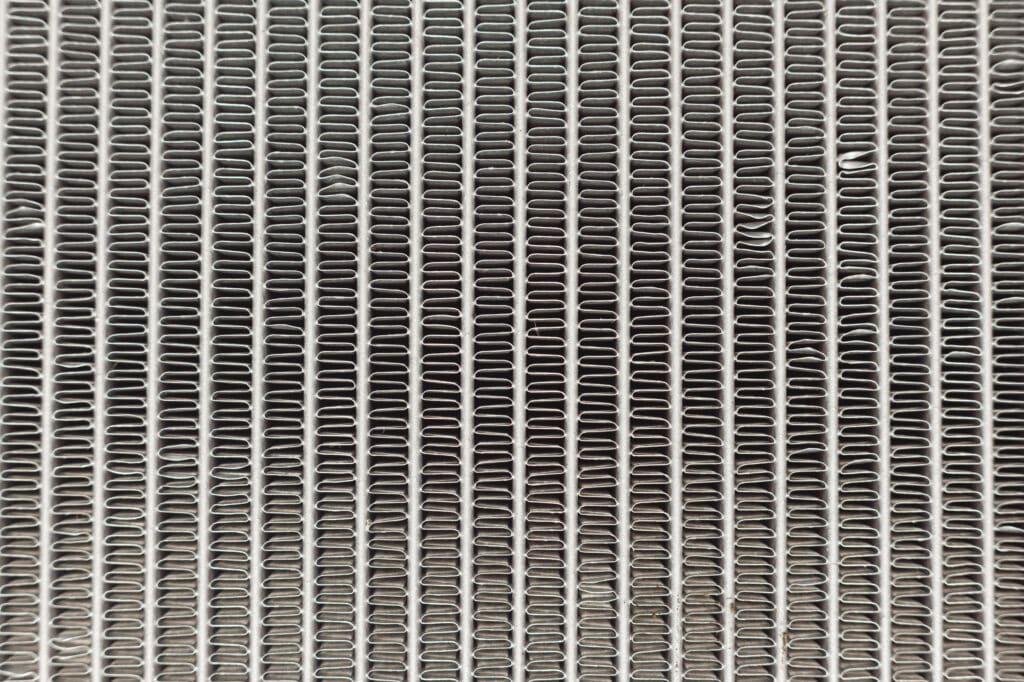

Finned-tube Heat Exchangers are another design variant that uses extended surfaces, or “fins,” to enhance the available surface area, promoting efficient heat transfer.

Operational Mechanism of Chiller Heat Exchangers

At the heart of any heat exchanger in a chiller are its core components: the evaporators, condensers, and the labyrinthine refrigerant circuits that snake through them. The design and function of these components vary depending on the chiller’s intended application and capacity.

When it comes to the flow arrangements inside these exchangers, there are primarily two configurations: counterflow and parallel flow.

- In a counterflow setup, the two fluids move in opposite directions, usually resulting in a higher temperature difference and, hence, a more efficient heat transfer.

- Parallel flow sees both fluids moving in the same direction.

Refrigerants are crucial players in the heat exchanger process. They absorb heat during evaporation and release it during condensation. The specific properties of a refrigerant, like its boiling point and heat capacity, can significantly impact the efficiency of heat exchange.

Enhanced Heat Exchange Techniques in Chillers

Modern chillers employ a range of advanced techniques to maximize their heat exchange efficiency.

1. Surface Area Augmentation Strategies

One such method is augmenting the surface area through designs like the finned-tube heat exchangers. More surface area equates to more space for heat transfer.

Microchannel Heat Exchangers are a boon for situations demanding compactness without sacrificing efficiency. They employ smaller channels for fluid flow and reduce the volume and the space they occupy.

2. Advanced Refrigerant Technologies

In the realm of refrigerants, there’s an ongoing push toward eco-friendly options. Low Global Warming Potential (GWP) Refrigerants are becoming the norm and offer efficient cooling without detrimental environmental impacts.

Additionally, the emerging Absorption and Adsorption Chillers utilize heat sources, often waste heat, to produce cooling that represents a sustainable and energy-efficient solution.

Chiller Heat Exchanger Efficiency Optimization

Beyond design, achieving optimal chiller performance requires sophisticated control strategies.

- Variable Frequency Drives (VFDs), for instance, adjust the motor’s speed to align with the cooling load requirements to ensure the chiller uses only the energy it needs.

- Chilled Water Reset techniques modify the temperature of the chilled water in response to external conditions, like ambient temperature, further economizing energy consumption.

- For an overarching control and monitoring solution, Integrated Building Management Systems (BMS) provide holistic oversight and operational control.

Today, the use of computational modeling and simulations has transformed the design process, which allows engineers to predict performance and pinpoint areas for improvement even before a prototype is built.

Chiller Heat Exchangers in Industrial Applications

Chillers are indispensable in industries requiring precise temperature control.

Manufacturing

In manufacturing industries, chillers are used to maintain precise temperatures for various processes. This is essential for ensuring product quality and consistency in industries like pharmaceuticals, food and beverage, chemical production, and more. Without proper temperature control, certain manufacturing processes could yield suboptimal results or even product defects.

Data Centers

Data centers house sensitive electronic equipment that generates significant amounts of heat. Chillers are essential in these environments to dissipate the heat and maintain an optimal operating temperature for the equipment. Efficient cooling is vital to prevent overheating and ensure the reliability and performance of data center infrastructure.

Ready to Offer Your Clientele Industry-Leading Chillers?

Dive into the extensive range at KKT Chillers USA. Our chillers boast superior performance, featuring state-of-the-art heat exchangers and advanced control systems for enhanced energy efficiency.

We offer a full range of chillers that are designed to chill applications for a variety of industries: MRIs, laser technology, and more. With our solutions designed to meet the needs of your clients, you can rest assured that your installation will provide lasting performance.

Get a quote for a chiller and drive your business forward.